Space Shuttle Launch Complex 39-B Construction Photos

Page 1

I did five years in structural steel construction management on Space Shuttle (Previously Project Apollo) Launch Complex 39-B when it was being converted from a Saturn V & Saturn 1-B, Apollo pad into a Space Shuttle pad, from 1980 through 1986.

Since I was in construction management, had access to the entire jobsite, and I also had a camera permit, I took a lot of photos, many of which wound up in photo albums that have been squirreled away, all these many long years since the early 1980's.

Recently, my son advised me that people might be interested in taking a look at things, as seen from the inside, as the structural elements of Launch Complex 39-B were erected and the launch pad took on its finished shape.

I just took the first page from one of the photo albums and placed in on the scanner and scanned it at 300dpi (the maximum resolution that my not-so-wonderful scanner will do), and it actually came out better than I expected it would, considering what we're working with by way of original images being scanned. The resulting whole-page image (OMBUU arm lift) weighs in at a little over 8 MB and it will be the first of many that will be displayed on these pages at a width of 1200px and which can be clicked to see the full-size versions, which will be roughly 2500px by 3500px in size.

I've got a lot of additional photos, including all of the swing-arm lifts and a lot of general shots of the pad from on the pad deck, as well as numerous shots taken from up in the structures of the RSS and FSS, and a few other places too. I've done a little poking around on the internet, and there does not seem to be anything else quite like these shots, readily and freely available.

If that turns out to be the case (and so far, and unless and until something changes, it certainly is the case), then that is both a sobering and humbling thing to consider. For those of you who wish to delve into detailed imagery and recounting of events that went into the modification of Launch Complex 39-B for the Space Shuttle Program, I'm all you're ever going to get.

The order in which these photos will be presented is a haphazard one, and follows the paging of the albums from which they were taken. Some are in series and sequences, but others appear to have been dropped into their locations in the albums randomly. Far too many years have passed since I created the photo albums for me to remember why I may have included things the way I did, and I shall not attempt to reconstruct things by guesswork. What this is, is what this is, and so it shall remain.

Here, and elsewhere, I shall express my undying and unlimited thanks to Manfred Rohr in Germany, who tipped me to the location of a set of structural steel demolition drawings which I could access for myself, and place them into what follows in the form of links to assist readers in understanding the layout, location, and physical particulars of the pad and its structural elements.

I shall also, at this time, request that if anyone knows how to acquire the Fabrication & Erection Drawings for Launch Complex 39-B or A, please let me know so I can incorporate them into this set of essays instead of the demolition drawings that I am perforce having to use right now.

I have requested access to the original drawings via the NASA Public Affairs Office without success. All requests I have made to any and all entities over the years have been denied. Why this might be so, I cannot fathom. These are historical documents, and to deny an interested general populace access to them seems counterproductive insofar as NASA has always had a strong institutional sense of history. Once again, should anyone ever gain access to the original Structural Drawings for the FSS and/or RSS on Launch Complex 39-B or 39-A, PLEASE let me know so I can improve my own humble effort to recount that small part of things which involved me directly, and which I might be able to provide perhaps the smallest bit of illumination for those who might wish to know more about what was done, and how it was done.

The complete set of abovereferenced demo drawings can be found here, but be advised that it's a substantial download, and comes in the form of a 90 megabyte, 106 page, pdf file, and is quite unwieldy to work with. I have excerpted it, and inserted the excerpts into what follows, as individual pages, which are much smaller in download size, and much easier to deal with, especially for anyone who might be reading this set of essays and looking at the linked images on lower-powered equipment.

Additionally, the excerpts that I include in what follows will, as much as is reasonably possible, be altered to reflect existing conditions as the pad was being initially constructed, when I was taking the included photographs, as opposed to how the pad came to be finally configured in its final form, prior to demolition, which is what the demo drawings I'm using show. As an example, I shall make mention here and now about the Orbiter Weather Protection System, which is included on the demo drawings, but had not so much as been imagined when we were first fabricating and erecting the RSS. The OWPS in its final form is a massive contraption of a thing, that hangs off of the front of the RSS as well as the north side of the FSS, and to the extent possible, I have removed that part of the OWPS, which wasn't there during my stay on the pad, as much as possible, from the excerpted drawings that will be linked to in the balance of this material. And, just to complicate matters a bit further, parts of it were included in what we were constructing. The GOX Arm Hurricane Lock is another large contraption shown on some of the demo drawings which wasn't there during my stay, when we were initially building the pad. And of course there are plenty of other examples, too many to enumerate individually. Basically, I want the excerpted drawings to match as closely as possible, the photographic images I am including in this series of essays. The alterations to the demo drawings only appear on the excerpts, and if you download the whole 90 megabyte, 106-page set, as linked-to above, you will be getting things as-is, without the alterations. So please be aware of that, ok?

And while I'm forewarning you of things, I suppose I'd better address the issue of acronyms, while I'm at it here, right up front, too.

NASA is in love with acronyms. Deliriously in love, actually.

And after a while, when you've worked out there long enough, the damn things just kind of soak into you, without you even realizing it.

And this series of essays is going to just be riddled with acronyms, so get ready for it.

Acronyms are a pain in the ass, and I do not like them (or any other form of opaque lingo), but they serve a purpose, and that purpose is brevity.

Who wants to write (or read) "Rotating Service Structure" over and over again, when you can use "RSS" over and over again? Nobody, that's who. Acronyms can be painful to the uninitiated, but they're for a reason, and make for a little less long-windedness here and there, so I'm going to speak my own language (most of the time), and I do hope you pick up on what I'm doing to help, with the introduction of each new acronym, but nobody can remember all of this crap, so I've created a handy page of every goddamned acronym that NASA was using during the Space Shuttle program, and I'm going to place a link to that page right HERE.

And I'll put another link to that page of acronym definitions down at the bottom of every page in this series, too.

Once you get to the acronyms page, you're going to have to find what you're looking for on your own, ok? CTRL-F (or ⌘-F for you Macish sorts) is your friend. Avail yourself of it, please. The total size of that document, acronyms and definitions together, is only 50,000 words, so I'm sure you won't have any trouble at all with any of it.

Above each full-page image scanned from the photo album (which, as previously mentioned, can be clicked upon for a full-resolution view), I will give a very brief thumbnail description, and beneath them, I shall elaborate and expand upon things further.

August 2019 note about scanned images: I have embarked upon a color restoration program for all of the images that I took with my camera. Time has been deeply unkind to the originals, which have, to varying degrees, suffered extensive color cast damage, sitting in the photo albums.

Embarking upon this work, I have discovered that the vagaries of the color-cast damage are amazingly varied and subtle, and can also vary strongly, even between scanned images that were taken mere minutes apart and photographically developed as part of a single roll of film, and which have been placed on the same page of the photo album, and scanned simultaneously.

Why this might be so, I cannot know.

But it's certainly there, and I have certainly had to deal with it, and that brings up another issue.

What constitutes "true color" when it comes to restoring these images?

The short answer is that there is no answer!

And my memory, while being pretty damn good, I'm told, is certainly not "photographic" and therefore I find myself having to take my best shot at it, and having to be satisfied with simply doing the best I can.

And there's more.

Much of the color-cast damage consists in alterations to hue, saturation, and value, which change, and are altered, across the breadth of a single image in such a way as to preclude global corrections to "true" for any given image.

And at this point, once I realized that unfortunate truth, I chose to simply "do the best I can" with each image, and let it go at that.

The images are herein presented above the detailed descriptions, first as a "whole page" rendering, followed, above such descriptions of individual photographs as are given, by individual photographs. In many cases, the color corrections for the individual-photograph images are different from color corrections for the whole-page image.

I have used my own eye, and my own best judgment, and oftentimes the corrections were applied with an eye toward bringing out this or that set of details or generalized area that could be expected to be of most interest to those who take the time to look at these images closely.

Links to the original scans are provided, full-size, for anyone who might wish to improve on what I've done by myself, and please be advised that I'm not a professional at this sort of thing, so I would expect that someone with a proper set of skills could make major improvements upon what you will be seeing herebelow.

What follows is just about one-half, as entertaining a personal history as I could write, and one-half, a full-tilt technical document. The technical parts can get hairy, and I'm fully aware of that. But if you want to know what went on, then you need to understand things, and since, after all, we were building a fucking launch pad, used by fucking rocket scientists, well... yeah, it's gonna get a little technical every so often.

And so, without further delay, I present you with:

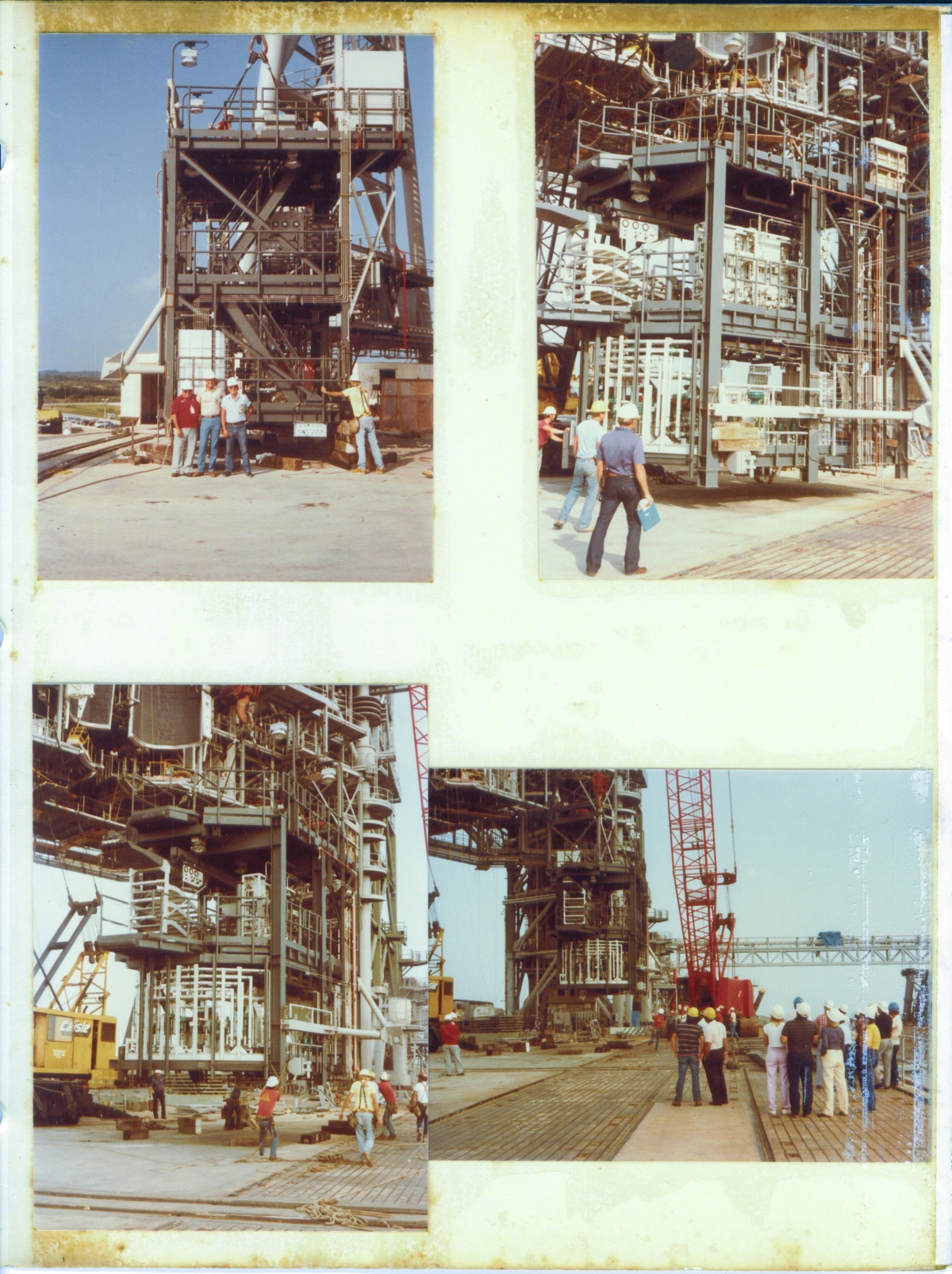

OMBUU Arm Lift 1 (Original Scan)

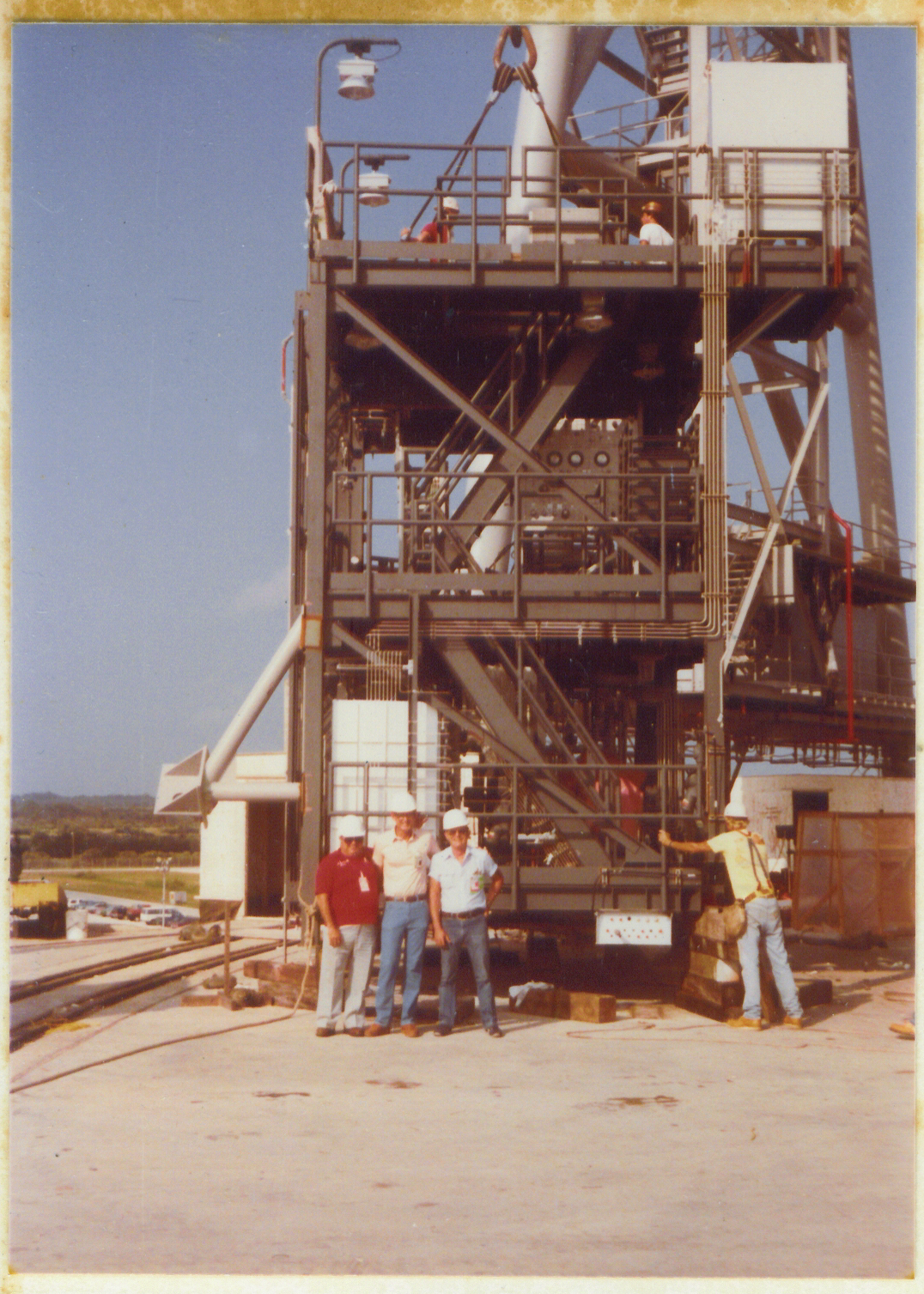

In the top left photograph of the below image, standing in front of the OMBUU (Orbiter Mid-Body Umbilical Unit) Arm facing the camera, are Howard Baxter, Wade Ivey, and a guy who's name eludes me. I'll try to identify people in shots if possible, but I am prosopagnosic to a substantial degree, so names and faces will oftentimes have to remain unknown, as my ability to recognize and recall them is impaired.

Top Left: (Full-size)

Why anybody ever called the OMBUU (pronounced "omboo" or perhaps better as "ahmboo" and never ever referred to as a proper initialism by enunciating each of letters) an "arm" I'll never know. It wasn't. It sat flush against the face of the RSS, did not swing or pivot on its own, and was certainly not longer than it was tall or wide. But everybody always called it the OMBUU arm. Ok, fine.

The OMBUU was fabricated off-site (By SMCI [Specialty Maintenance and Construction Incorporated] in Lakeland, I think, but that memory is a bit faded and could easily be wrong.), and trucked to the pad and deposited near the foot of the pad slope, where it sat for a pretty good while, prior to getting lifted and attached to the RSS.

The OMBUU was quite sturdy. Vastly moreso than you might imagine. The iron which it was made from was far heavier, and far more closely spaced and braced, than you would ever think that a thing this size would need. I'm sure that its location right up against the left side of the Orbiter, in conjunction with its duty as the support for the umbilicals that serviced the Orbiter's fuel cells (which employed the use of Liquid Oxygen and Liquid Hydrogen, both of which are insanely cold, volatile, explosive, and just generally nasty things to be working with) must have had something to do with its very robust construction.

Here are the six structural drawings for it, if you'd like to see for yourself, what it was made out of. One. Two. Three. Four. Five. Six.

When it came time to take it up to the pad deck it was very unceremoniously lifted by a crane and placed on the back of a common low-boy semi-trailer which had been modified in no way, and driven slowly up the pad slope with lots of us management types watching the operation, and an ironworker on either side holding on to taglines attached to the top of it as it swayed and wobbled along, going upslope. I distinctly recall being horrified by the astoundingly causal approach everybody took to things, including all of the present and attending NASA oversight (It was their arm, right?), and found myself constantly wondering what, exactly, a 200 pound ironworker was going to do with his tagline should the flexing and side-to-side rocking of that low-boy have gotten to the point where the damn thing was going to tip over. But of course nothing of the sort happened, and all of my fears and worries turned out to be completely unfounded, and I'm not an ironworker anyway, so I kept my big stupid mouth shut and everybody did their job, and that was that.

Howard Baxter (red shirt, left) was the "Pad Daddy" and he was a fearsome sonofabitch, and brooked no bullshit from anybody for any reason, but was also rock-solid, straight level and true, FAIR about things. I liked Howard a lot. How he may have felt about me, I do not know, but he at least put up with me to the extent of letting me do my job whenever he was around, instead of summarily running me out of the TT&V field trailer up on the pad deck, as I was witness to with certain other less-fortunate souls. He was lead for Boeing's TT&V (Terminate, Test, and Validate) group who held the contract with NASA for seeing to it that things were installed correctly on the pad, and seeing to it in a most thoroughgoing and rigorous manner.

Wade Ivey (tallest member of the little three-man group, center) owned Ivey Steel, for whom I worked. Wade was an ex-ironworker who started his own steel erection company and became quite successful with it out on the Cape. He was easy to get along with, but knew his shit backwards, forwards, and sideways, and nobody was going to get anything past him, ever, when it came to his company and his work operations. He succeeded as well as he did because he knew his shit, and was willing to put in the time to get it done, whatever it might have been that needed doing. He consistently turned a profit, getting contracts and doing work that others could not bid as low, and got it done per the plans and specs. Which pretty well sums it up, right there.

Our third member of the little three-man group, alas, must remain unnamed, as I have a substantial, but not global, case of prosopagnosia and am not worth a shit with names and faces. I do know that he was NOT John Bell, and it was him, and John, and Howard that you would most frequently encounter in the Boeing TT&V field trailer riding herd on multiple contractors doing a myriad of things in a bewilderingly complex and dynamic construction and modification environment, but damned if I can remember his name. Sigh. He was another one of those people you meet in areas where the general level of things is quite a bit higher than what you tend to encounter in daily life, on the street and elsewhere, and he was crackerjack at his discipline.

To the right, facing away, leaning against the OMBUU as it was just about to start floating away from the cribbing that had been supporting it as the lift commenced, an ironworker (perhaps Rayburn Chiles, perhaps not) is there to steady things as they start to happen. If the crane is not dead fucking center above its load, that load will "drift" as it breaks free from its contact with whatever had been supporting it on the ground. Although our assembled participants give no indication of it, this is a dangerous moment, and I'll leave it up to you guys to google for what can occasionally happen when a lift goes wrong. It's not pretty, and people do get killed now and then. Which means we're dealing with a pretty ballsy crew here. Every one of these people knows exactly what's going on with this lift, knows the risks, and yet all of them are happy to trust their lives with the crane operator and the ironworkers who are working with him on the lift. High praise for everybody. Not as if they need it or anything, though. They already know exactly who they are and exactly how good they are.

You can see a couple of ironworkers on top of the OMBUU, squaring things away with the sling that it was about to get lifted with. Maybe take note of the thickness of the wire rope that the legs of that sling are made of. The OMBUU was heavy.

In the background, far left, you can see the cars that were parked in front of all the contractors' field trailers. You're looking down on them because the pad deck is roughly fifty feet above ground level. The pad's a very large object, and lots of times when you're looking at pictures of things on the pad its easy to lose your sense of scale. Everything is giant out on the pad. The Space Shuttle is giant, so everything that is associated with it has to be giant, too.

Behind the OMBUU, you can see a portion of Column Line 7, which supports the RSS (Rotating Service Structure, which is invisible, out of frame above it. The RSS had seven main column lines. Column line 1 was the Hinge Column which extended to the ground, around which the RSS pivoted, and Column line 7 was the far end of things, and also extended to the ground, and rolled on a special curved rail track, out and around the Shuttle, when service work was required upon it. Between those two column lines, the rest of the RSS was essentially a fifteen-story high-rise office building (or maybe a research center, or perhaps a machine shop), hung in suspension sixty feet above the ground, and the whole goddamned thing rolled, or more accurately swung like a cyclopean door of some kind. Impossible to describe. I need to shut up.

Top Right: (Full-size)

In a yellow hard hat is Rink Chiles (brother of Rayburn), Ivey Steel's ironworker general foreman for this project. Rink (his actual name was Reynsol) taught me an amazing amount about the business of real-world structural steel erection during the time we worked together for Ivey Steel. Rink was one of those deceptively country kind of backwoods sorts who could think circles around just about anybody he met, but never let on about it much, unless and until it was actually required as a job unfolded. There are times when I think it was all just a very coldly calculated deliberate act to give him the best possible footing whenever he need to ambush somebody to clear them from his path when he was working to get somewhere. Fiery disposition. Not to be crossed. Lethally intelligent. Does not play well with other children.

My kind of people.

In a while hard hat, holding what appears to be a clipboard, is Jack Petty, tech rep for BRPH, who had another contract, completely separate and distinct from Boeing's TT&V contract, for engineering oversight of the construction and modification efforts that were ongoing when these pictures were taken. Ex-ironworker. Tough as nails. Sharp as a tack. Fair as it gets. Yet another one of those difficult no-nonsense people that I find myself drawn to and getting along with best, wherever I fetch up. Jack was the other principle in the infamous Techno Redneck story that I've placed elsewhere on 16streets.com.

In this image, the OMBUU is now clear of the ground it is gliding just above, controlled by the hands of the crane operator, who is being directed and reported to by the ironworkers. The OMBUU now hangs freely suspended from a wire rope descending well over a hundred feet downwards from the end of the crane boom, completely unseen, far above it. The damn thing weighs more than your house and yet it sails along smoothly a mere foot or so above the ground, as if it was a child's toy. There shall never be any way that I can properly convey the professionalism and expertise of the crews that do this kind of thing for a living. No fucking way at all. Hats off to every one of you sonofabitches. In the background, the RSS above, and the FSS Fixed Service Structure) to the right, loom in all of their bizarre complexity.

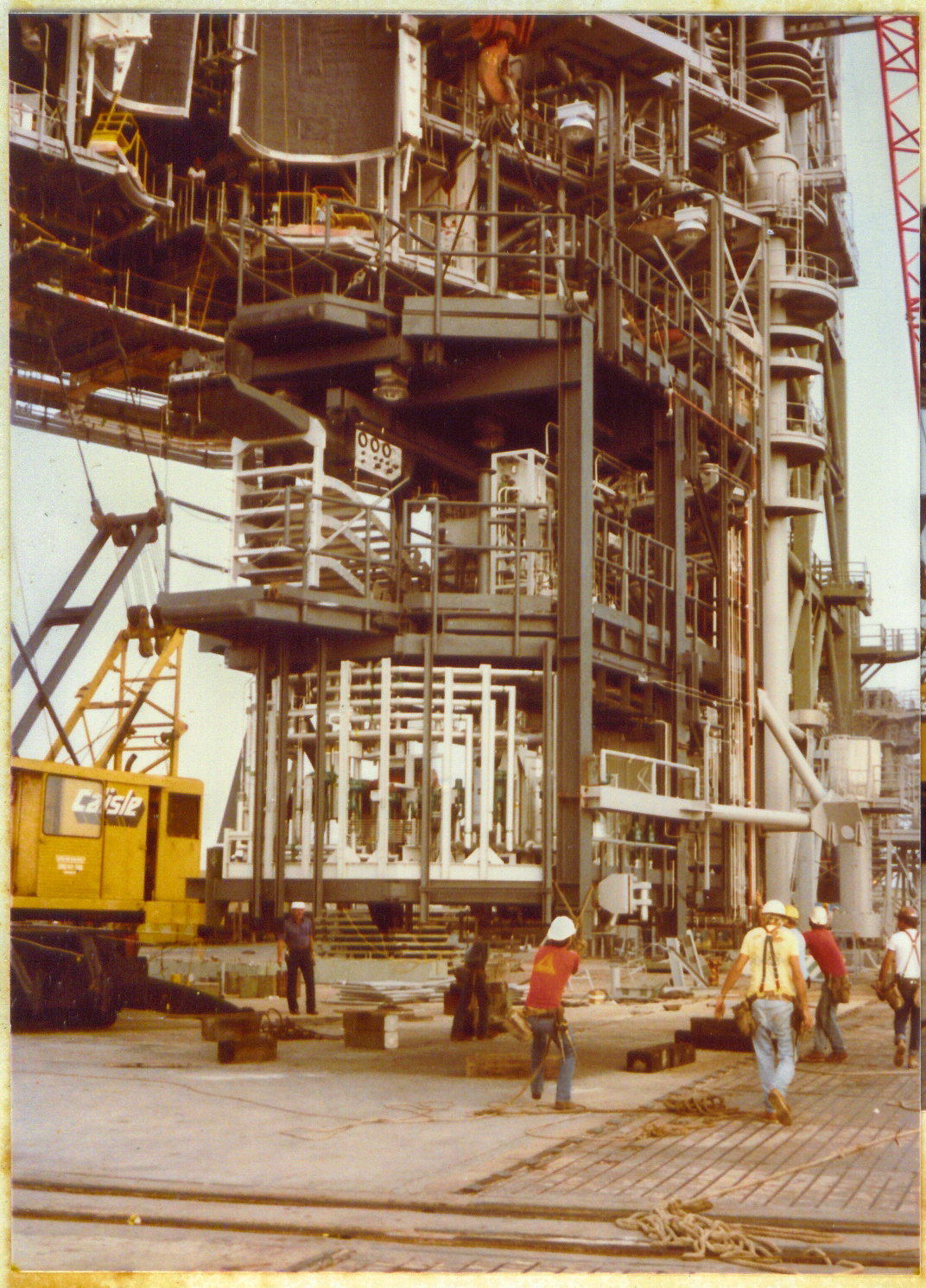

Bottom Left: (Full-size)

The OMBUU has by now reached the place from where it is to be raised straight up, prior to being deftly, delicately, and dangerously worked into its final resting place, hard up against the support steel that is waiting for it, a hundred feet up amongst all that confusing welter of structural steel above it. It has just begun its upward journey, and the ironworker in the red shirt closest to the center of the picture is hauling pretty strongly against his tagline, working to keep the damn thing oriented in place, where it belongs, as it rises. On the far side, Jack Petty is keeping an eye on things, and it's all in the hands of the crane operator at this point.

In the background, partially covered by the OMBUU on its right, the Hinge Column for the RSS can be seen. That thing was a complete story in and of itself. But not now. Above the OMBUU, more of the RSS is coming into view, including the OMS Pod Heated Purge Covers, (about which unpleasantly more, later on, but not right now) partially visible left side, top edge. Maybe take note of the size of the crane hook, red, hanging down from the top edge of the picture in the center, and compare it with the people you see elsewhere. Heavy stuff. Lotta heavy goddamned stuff all over the place.

Running along the bottom of the frame, a short segment of the two rails which carried the RSS as it rotated through 120° of travel between the mate and de-mate positions it would be locked down in, can be seen.

When the Space Shuttle was on the launch pad, the RSS would be rotated around into the mate position to service it. When the Space Shuttle was elsewhere (which is most of the time), the RSS would be rotated back into the de-mate position, which is where you will be seeing it appear in almost all of these photographs.

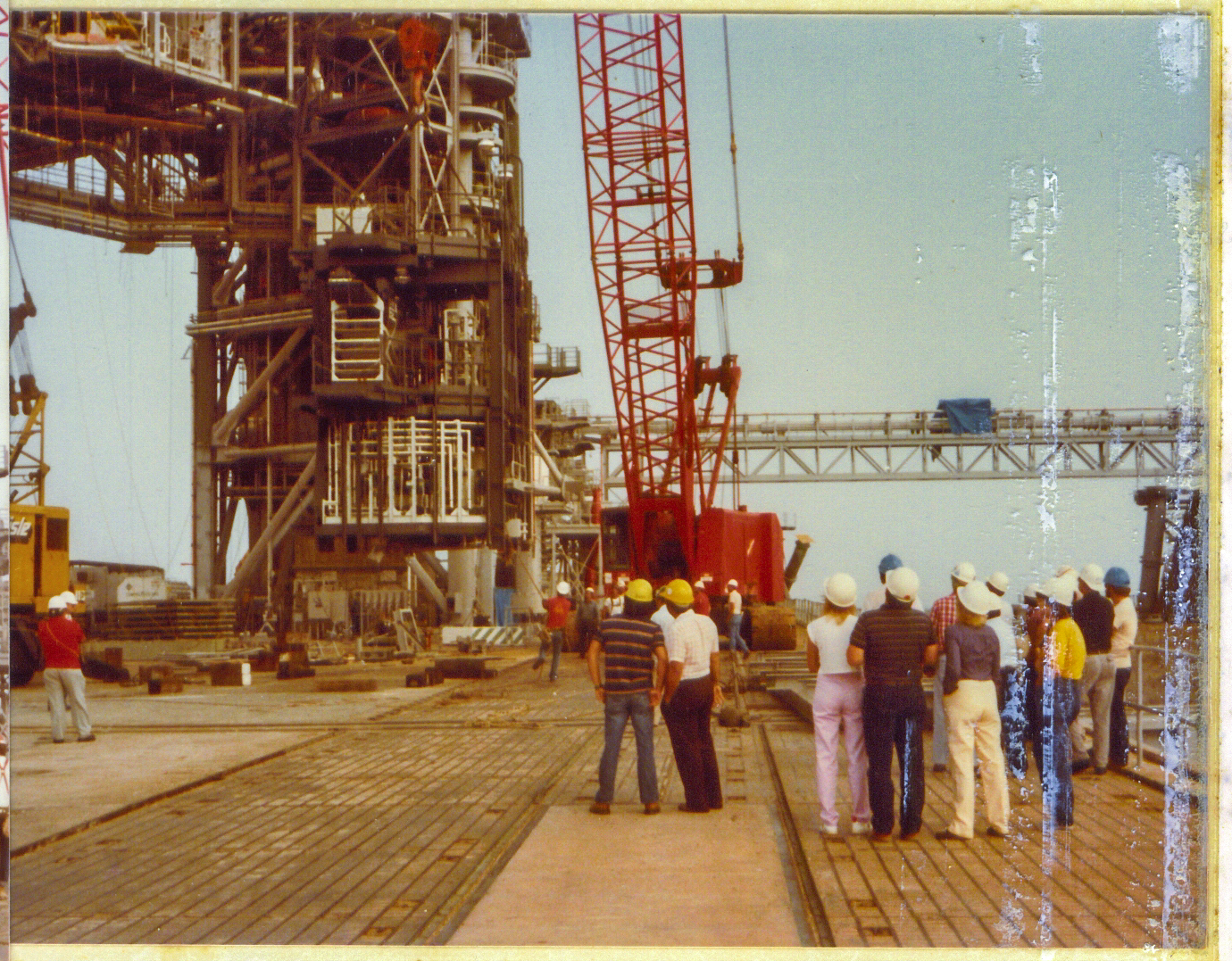

Bottom Right: (Reduced 1200px wide. Click image for full-size 1380px wide)

And up it goes. Howard and Wade are over on the left side, discussing something or other, and everybody else has positioned themselves out from under the suspended load, even as our red-shirted ironworker continues to give it his all, one-footed by now, on the tagline.

In the distance, the big Manitowoc crane which is performing the lift is now visible, and in front of it is the crowd of people who always find a way to come and view operations of this sort, only a few of whom actually belong up on the pad deck at this time. Of note is the individual in a blue hard hat, farthest right, ever-so-casually leaning back against the handrail that surrounds the edge of the Flame Trench. That's a fifty foot sheer drop to flat concrete, invisible in this picture, right there behind him, and if it turned out that the handrail post was rusted near-through at the bottom, or perhaps the ironworkers had cut it completely loose in preparation for some modification or other and it was just sort of "resting" there, or who the hell knows what else, then he's a dead man. Never lean back against the handrail, ok? Just don't do it. Stay away from that shit. Leave that shit alone.

The group of people on the right, as well as our red-shirted ironworker working the tag line on one foot, are all standing on the part of the pad deck that directly supported the crawler-transporter.

The crawler had a pair of tracks on either side, and with the MLP carrying a fully-assembled launch vehicle on its back, it was heavy.

One pair of tracks would be on this side of the flame trench, and the other pair would be on the other side of the flame trench, completely out of view in this image, to the right.

Each area on the pad deck that directly supported the crawler was reinforced with additional 1"-thick steel plates embedded vertically in the concrete, the edges of which which can be seen beneath the feet of those standing upon it as a series of closely-spaced lines (there was also steel reinforcement running transversely, but it does not show very well in this image). This area had to be strong, and even this was not quite enough to ensure that the crushing loads did not damage the pad surface. Along the edges of the steel-reinforced areas which the crawler tracks came in direct contact with, 3" x 3" angle iron was placed, full-length. You could trip on these if you were not paying attention, walking around up there, and occasionally people did, much to the merriment of everyone else around who caught them in the act. When it came time for the crawler to be moved to the launch pad, NASA would lay plywood sheets down, covering all of this steel-reinforced area, between the angle-iron, and in that way distribute the load just a bit more smoothly and evenly across that part of the pad deck which the crawler tracks were bearing down upon. Once it had served its purpose, and the MLP had been secured upon its support pedestals, the crawler would be returned back to the area of the VAB, and the plywood would be removed. Needless to say, after serving this purpose just once, the plywood sheets were useless for anything else, and had to be discarded.

Return to 16streets.comACRONYMS LOOK-UP PAGEMaybe try to email me? |